About us

Home > About us

Historic pionner of the solar industry for 40 years, today we are a leader in the production of low carbon ingots, wafers and high efficiency photovoltaic panels.

How do we create solar panels?

Silicon

Metalloid existing in various forms such as quartz, it is the second most abundant element on earth

Ingot

Silicon melted in ingots and crystallized while reaching 1500°C

Brick

The ingots are cut into bricks before the polishing process and infrared inspection through silicon

Wafer

The bricks are cut into slices of

170 to 190 µm to produce LOW CARBON wafers

Cells & photovoltaic panels

Texturization of wafers, junction by phosphorus diffusion, contacts serigraphs.

Assembled by historical partners

Recycling

Photowatt is co-founder of SOREN, a solar panel is 96% recyclable.

Silicon

Metalloid existing in various forms such as quartz, it is the second most abundant element on earth

Ingot

Silicon melted in ingots and crystallized while reaching 1500°C

Brick

The ingots are cut into bricks before the polishing process and infrared inspection through silicon

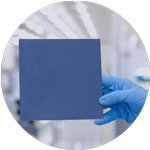

Wafer

The bricks are cut into slices of

170 to 190 µm to produce LOW CARBON wafers

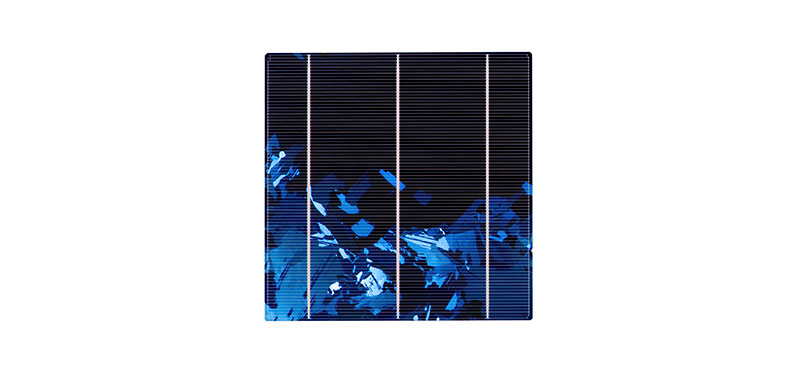

Cells & photovoltaic panels

Texturization of wafers, junction by phosphorus diffusion, contacts serigraphs.

Assembled by historical partners

Recycling

Photowatt is co-founder of SOREN, a solar panel is 96% recyclable

Recycling

Photowatt is co-founder of SOREN, a solar panel is 96% recyclable

Cells & photovoltaic panels

Texturization of wafers, junction by phosphorus diffusion, contacts serigraphs.

Assembled by historical partners

Wafer

The bricks are cut into slices of

170 to 190 µm to produce LOW CARBON wafers

Silicon

Metalloid existing in various forms such as quartz, it is the second most abundant element on earth

Ingot

Silicon melted in ingots and crystallized while reaching 1500°C

Brick

The ingots are cut into bricks before the polishing process and infrared inspection through silicon

Key figures

Our history

1979

Starting up as a research organization

Creation of Photowatt as a research center as a spin-off from Philipps (development of photovoltaic cells for satellites)

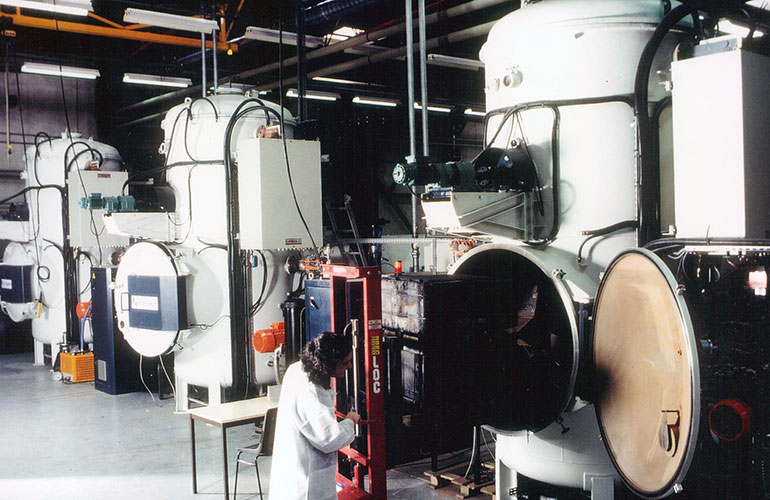

1984

Photowatt becomes producer

The company will broaden its vocation and take on an industrial dimension. Photowatt switches from 4-inch monocrystalline cells to multicrystalline silicon, thanks to the POLIX melting process that it has designed and industrialised itself. At the same time, it initiates the development of the first wire saws, used today by most manufacturers in the sector.

1990

Moving to Rhône-Alpes

The company moves to Bourgoin-Jallieu to expand and get closer to the industrial and research centres of Lyon and Grenoble in the Rhône-Alpes region. Photowatt remains a company with a production capacity of 3 MWp.

1997

New industrial dimension

The capacity is increased to 13 MWc, following the acquisition of the company by ATS. In 2001, Photowatt increases its wafer and cell manufacturing capacity and acquires a photovoltaic panel assembly line.

2000

Photowatt in the world's top 3

With Siemens and BP (Solarex) on Monocrystalline and Polycrystalline technologies.

2007

Launch of PV Alliance

Launch of PV Alliance with EDF ENR and CEA within Photowatt to develop high efficiency cells.

2012

Integration into the EDF Group

Photowatt and PV Alliance become 100% subsidiaries of EDF Renewables.

2016

Crystal Advanced® Technology

Launch of photovoltaic panels and cells in Crystal Advanced® monolike technology, which offers high performance at low cost and a low carbon footprint.

2018

New industrial model

Increase in the production of low carbon ingots and wafers for the production of high performance monolike photovoltaic panel.