Photovoltaic products

Home > Photovoltaic products

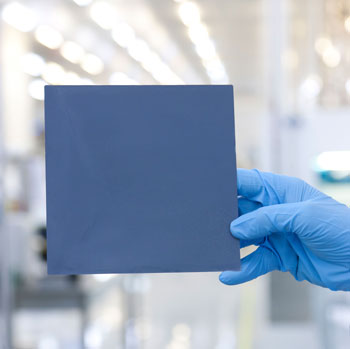

Photowatt specializes in the low carbon production of high-tech silicon ingots and wafers to produce high-efficiency photovoltaic modules.

Our range of photovoltaic products

Monolike Crystal Advanced® technology

The photovoltaic industry has historically been based on 2 crystallization processes:

- the “multi” process, which consists of producing multicrystalline ingots with a square cross-section, and

- the “mono Czochralski” process, which produces cylindrical monocrystalline ingots from a seed dipped in liquid silicon.

With 40 years of know-how in silicon crystallization, Photowatt has developed an innovative hybrid process, consisting in producing “mono-like” ingots, using classic “multi” directional solidification furnaces, but containing more than 95% of single crystals.

To do this, the French manufacturer has completely rethought the thermal properties of the ovens in order to trigger crystallization at the right time and to control all the physico-chemical parameters, in order to obtain crystals that trap a maximum of light and thus increase the current produced by the photovoltaic cells.

The substrate thus obtained allows the products to reach a high yield, a greater longevity and lower costs than the traditional production methods, with equivalent yield. Moreover, its carbon footprint is 33% lower than that of mono*, giving it a substantial competitive advantage for French tenders.

(*) According to CRE methodology

Quality & Reliability

Photowatt products are all quality products with the best performing components on the market. Product reliability is a priority for the company, which carries out tests that exceed the industry standard.

ABOVE STANDARD TESTING

We carry out tests on the entire production chain, which allows us to have quality, durable and reliable products over time.

Photowatt meets the requirements of IEC standards, but also performs reinforced tests on the most critical tests (eg: 2x 1000h of damp heat, 2x 200 cycles of rapid temperature variation, PID, etc.).

QUALITY CONTROLS

Photowatt also performs quality controls throughout its production chain.

100% of the photovoltaic modules are subject to electroluminescence (EL) inspection in order to eliminate defects in the core of the materials, dielectric checks and I / V measurements are carried out using an AAA solar simulator present in our factories .

Our metrology equipment is calibrated with the most renowned independent institutes (e.g. Fraunhofer ISE).

Zoom on our photovoltaic products

Drag the cursor over the circles and discover the details of the components of our modules.